Increasing enmity between China and the West, stemming from China’s increasingly aggressive actions regarding Taiwan, China’s COVID-zero policy and a whole host of other issues have caused foreign companies that do business in or with China to reassess. See Nancy Pelosi’s Visit to Taiwan is Really Bad for Your China Business and Sourcing Product From China Just Got Even Riskier.

With all that has been happening, the international manufacturing lawyers at my firm have been seeing an uptick in phone calls and emails from companies looking to leave China. Most of these companies want to know more about Mexico. Some of these companies are actually Chinese and Taiwanese.

I asked my good friend Andrew Hupert to explain what is involved in moving manufacturing from China to Mexico, in large part by comparing the two countries. I chose Andrew for this near-Herculean task because he has spent so much time in both countries navigating their manufacturing systems from the inside. My law firm frequently consulted with Andrew when we first started doing China legal work in a big way and at that time Andrew was living in China. Though Andrew had for decades tied his life and career to China, like me, he was one of the early proponents of a post-China manufacturing world. So much so that Andrew moved to Mexico, reinvigorated his Spanish language skills and began helping companies — especially companies looking to leave China — navigate Mexico. Who better, then, to write about what it takes to leave China (in whole or in part) for Mexico than Andrew Hupert?

Andrew has already written the following four posts on the differences between China and Mexico manufacturing and I urge you to read all four of these:

- The China Manager’s Guide to Mexican Operations: Comparing and Contrasting China and Mexico Operations

- Mexico for China Managers, Part 2: China vs. Mexico as Supply Chain Hubs

- Part 3: Comparing China and Mexico Manufacturing at the Operational Level

- Mexico for China Managers, Part 4: A Guide to Cross-Culture Negotiation

The below is part five of what has become a long-running series, with no end in sight. This episode deals with determining the best candidates for moving their manufacturing from China to Mexico.

Over to Andrew for part 5. . . .

China cemented the “factory of the world” title back at the start of the century, with the Canton Fair and Hitech Shenzhen characterizing the general Blade Runner/anything-is-possible vibe of manufacturing there. If you had a design for a widget scrawled onto the back of a napkin and a few thousand dollars on hand, you could get your product made in China. The punchline that used to follow would be about shoddy quality or disappearing agents – but in fact the general level of quality and transparency in China had improved significantly up until the recent “difficulties” (Covid, lockdowns, geopolitical tensions, tariffs, trade restrictions, logistics bottlenecks, droughts, floods, fires, war, stock-market crashes, etc.).

The China Way

A big part of the “China Magic” was tightly integrated clusters of manufacturers and distributors, all bound together in a complex, informal network of personal relationships. When I was in Shanghai, the typical problem-solving scenario was for four or five engineers to huddle in a stairwell with a pack of Zhongnanhais and come back 20 minutes later with a plan for a work-around, some part they sent the youngest team member pedaling off to get, and the name of the guy nearby with the machine/know-how needed.

The Mexico Way

This is NOT the procedure in Mexico – where glitches, bottlenecks, and supply chain adjustments tend to go up through well-established official channels – often running through Dallas TX, Deerfield IL, or Detroit MI.

When I talk to production people in Mexico, they are quick to differentiate between companies that are “production-ready” and “companies with products”.

“Production-ready” means that dedicated operations specialists will show up with detailed information on the product, the parts, the process, and the people. These are typically in the auto industry (or those closely integrated with that supply chain), aerospace, and large-scale assembly. They are coming from the U.S. or Europe with specific plans and looking for local Mexican partners who can construct facilities, manage regulations and relationships, and help with staffing & operational functions (accounting, payroll, HR, etc.).

And what about the others? Those businesses that emphasize the marketers or product developers and ended up leaning too heavily on their Chinese OEM factory managers for the nuts & bolts operational decisions? Some unnamed factory manager in Shenzhen knows more about the production process, parts & materials, suppliers, and the IP than the owners, in many cases. This wasn’t (necessarily) anything nefarious – Chinese engineers enjoy a hard-won reputation for process innovation and figuring out how to make it all work. But it makes transitioning to a new manufacturing base much more difficult.

Contract Manufacturing, or OEM (Original Equipment Manufacturer), was elevated to a commodity service in China, and a whole industry sprang up around back-tracing Alibaba merchants to find the factory owner who could tweak or feature-up an existing design for sale to U.S. buyers on Amazon.

If you’re not clear on the concept of OEM, think of the relationship between Apple’s iPhone and Foxconn. Foxconn is an Original Equipment Manufacturing (OEM) company that does not own its own consumer brands, designs, or IP. Its sole business is mastering and overseeing the production process for others such as Apple. Apple designs the products and Foxconn designs the production process. Foxconn delivers iPhones to Apple and gets paid for each piece it produces. That’s the OEM model that helped make China the production leader it is today. But now, no one really wants that business, including Mexico.

Those of you used to the goal-driven, “gettr dun” attitude of Chinese factory managers will have to adjust to a much more U.S.-centered management style. Mexico is a world of ISO 90XX certifications and “The Toyota Way” of process engineering. They are head-down managers who consider the only valid proof of a process to be actual, verifiable performance. Mexican factory managers aren’t big on “leaps of faith”, just like their north-of-the-border counterparts.

Chinese factories will take a job if they are reasonably sure they can do it. Mexican factory managers will say no to projects that feel improvised or “patched together” or difficult to replicate.

Mexico’s Approach to Manufacturing Has Two Big Implications for China Managers in Transition

1. Most of you will need your own production facility. The OEM model of contract manufacturing that China offers is not common here.

2. You will have to adjust, because the Mexican Vision Thing – risk-averse, siloed communication patterns, respect for standards and best practices – may seem a bit restrictive to you at first. Decision-makers from China may be tempted to plunge ahead with solutions that they think others are missing. There may, however, be good reasons Mexican managers are operating the way they do. Work on surfacing their concerns before spitballing innovative solutions.

The Three Types of Organizations Moving Their Manufacturing to Mexico

Let’s break down the production world into three groups: 1) The Production-Ready; 2) The Product Company; and 3) The Virtual Storefront.

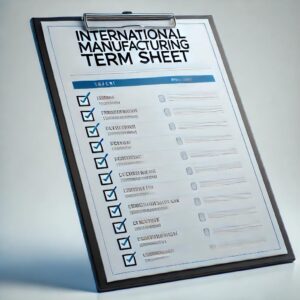

1. Prime Candidates for Mexico Manufacturing — Production-Ready Companies

You are “production-ready” and you have the receipts. You are in control of your own production process, sourcing, and logistics. You know how your product is built, you have the molds, the IP, and the list of suppliers with all the paperwork and data needed to start your own production process. There is a good chance your company already has contacts and facilities in Mexico.

Mexican standards of “production-ready” have been set in stone by the Maquiladora factories along the border. These are U.S. factories that happen to be located in Mexico. Heavy hitters of process engineering – GM, Caterpillar, Ford, etc. – maintain cutting edge facilities in Mexico. Engineering standards are very high – but not very flexible by China standards.

If your organization is expanding production in Mexico, it may be a very orderly process. If you are trying to transition from China to LatAm internally, Mexico might be someone else’s turf already, as it’s considered a pretty desirable territory. Look at Peru or Columbia to gain necessary experience and exposure.

If your organization is new to Mexico, a little research will go a long way. Even if your company checks all the right boxes (size, industry, technology, ownership), you may find it challenging to get land in certain regions.

2. Potential Candidates for Mexico Manufacturing — Product Companies

If you are willing to invest in your own production/assembly facilities, you can probably find people to help you source and set up your production process. This definition covers a lot of people, and you might be one of them.

You’ve got a bit of a Catch-22 walking into Mexico, because you will be expected to provide a lot of plans and answers and solutions about the very topics that you know the least – by the people you have just hired to help you figure it all out. After a few years doing business in China, you might be used to connecting a wide array of dots to come up with innovative solutions. In Mexico, the people you are relying on are much more comfortable with a tried and true solution that everyone understands beforehand. Improvisation is not a valued skill for Mexico manufacturers.

Also, remember that in Mexico you are hiring/providing your own factory management – which means that the local version of “that guy who takes care of things” in Shenzhen is now on YOUR payroll, and probably looking at YOU for ideas and solutions. You will have to come up with not only product designs, but also a full plan for sourcing materials and components.

Never forget that Mexican factory culture is set by the Maquiladoras / Immex program — developed with/by U.S. manufacturers to align Mexican and U.S. production processes. These decision-making chains are not interested in ad-hoc, jury-rigged solutions that cost little but guarantee nothing. The good news is that your experience and skills from Asia will give you the super-power of spotting new opportunities, potential services, and underdeveloped relationships. The bad news is that even the ideas that seem pretty mundane to you may be greeted with indifferent shrugs by local managers who just don’t see the point of innovation for the sake of innovating.

3. Iffy Candidates for Mexico Manufacturing — Virtual Storefront Companies

China as the “Factory of the World” accommodated an incredible range of companies. Foxconn and Tesla were/are at one extreme – massive, cutting edge, and expensive. At the other end of the spectrum, plenty of plucky entrepreneurs built brands using “virtual factories” that were in actuality just a string of contract manufacturing agreements. In Shenzhen you can probably still do it. In Mexico you never could, and almost certainly won’t be able to soon. Mexico doesn’t really do virtual, especially not on a large and multi-factory scale.

If your business model features small quantities, customized outputs, and low-cost materials, then you have been benefitting from uniquely Chinese elements of production and logistics. Your small production runs may be the tail end of a larger customer, or you may be taking advantage of excess capacity in busy production centers – but short-term informal access to manufacturing capacity is more the exception than the rule in Mexico.

Not every idea is going to work in Mexico, and your first analysis should always be a feasibility check.

The Final Word on Transitioning Manufacturing from China to Mexico

Transitioning your supply chain from China to Mexico is definitely the right move. . . . for some organizations. Others will have to find another solution.

For the vast majority, however, the reality is some place in between. Mexican managers are great at doing what they do all the time, and you will end up with great facilities and the best possible business set-up. But some problems that would be considered minor challenges in China will kill deals here if you let them.

You’ll also be expected to know everything about your company’s production, sources, materials, and supply chain. Your China network may not be excited about sharing all of that, so you have a project in front of you. Learn everything you can about your own production. It might be a bigger project than you think, but it’s probably something that you should know anyway

So, is Mexico right for you? Spoiler alert – if you’re looking for low-cost production targeting the U.S. market, you should consider Mexico as a part of your future. But if your production needs are non-standard, unpredictable, or if you are simply in an industry that Mexico doesn’t do, then you may have to look elsewhere. Just remember – after China, any other production center or logistics hub is going to seem highly DIY and management intensive. Get used to it.

Andrew Hupert splits his time between the United States and Mexico (mostly Saltillo and Oaxaca) where he helps international businesses expand or adjust their supply chains. After over 20 years in Asia (Shanghai, Taipei, HK, Saigon), Andrew decided to follow his own advice and move his operations closer to home. You can contact Andrew at Andrew@JLAsociados.com.mx, or connect with him on LinkedIn.