How to Successfully Source Product from a Contract Manufacturer

Imagine investing hundreds of thousands of dollars into manufacturing a new product, only to receive a shipment that bears little resemblance to your original design. This is a reality faced by a U.S.-based electronics company that reached out to our law firm last year. They had overlooked the critical importance of a detailed specification sheet in their manufacturing contract with their China manufacturer, and this resulted in their recieving unsellable products. This costly oversight highlights a stark reality: the success of sourcing products from contract manufacturers hinges significantly on the precision of your spec sheets.

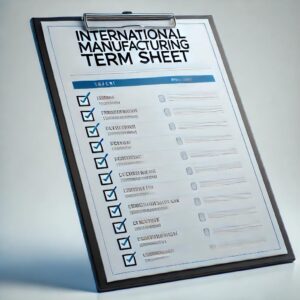

When I give speeches on what it takes to successfully source product from a contract manufacturer, I always emphasize the following four things:

- A good manufacturer. This is accomplished by conducting sufficient due diligence on your potential manufacturers.

- A good manufacturing agreement, to include spec sheets if appropriate. If not appropriate at the time, than it should make clear that future Purchase Orders (POs) that include spec sheets will automatically be incorporated into the manufacturing agreement.

- A good IP protection.

- Good quality control.

Years ago, my law firm’s international manufacturing lawyers drafted manufacturing agreements for 26 (!) different countries for a sophisticated client with a sophisticated in-house lawyer. During one of our conversations, this lawyer emphasized the importance of the specifications sheet for his company and talked about how the company had specific instructions on how to draft company spec sheets. I asked if he would send me those instructions for this blog. He did, and I am finally getting around to running it, below.

We typically draft our cross-border manufacturing agreements to incorporate our clients’ spec sheets (a/k/a data sheets) as an Exhibit to the manufacturing contracts. When it is not possible for our client to include the spec sheet with the contract, we often suggest they include it as part of their Purchase Orders (POs), which in turn are specified as being incorporated into the Manufacturing Agreements we draft. When I lecture on the importance of having a good Manufacturing Agreement, that includes having a good spec sheet.

Manufacturing Spec Sheet Instructions

Note that the below spec sheet instructions are for one particular company, and your requirements likely will vary enough from this company’s so as to make these instructions not perfect for you. But it should be a good start.

According to this company’s instructions, all spec sheets should contain the following:

- Product description

- The SKU

- The specific materials for the product and the precise amount

- Product dimensions

- Product tolerances (if any)

- The Pantones (product colors)

- Testing requirements

- Price

- Order quantity

- Label specifications

- Packaging specifications

- Shipping specifications

- Special instructions

- Photographs of the product from multiple angles and with the dimensions indicated

The instructions also mandate listing “every appropriate detail not set forth above” and that everything be described in “as much detail as possible”. They also instruct “confirming with the manufacturer that you have not overlooked anything” and “that the manufacturer has everything it needs to know exactly what to manufacture.” In drafting your spec sheets, always remember that in many countries, if something is not in writing, for legal purposes, it essentially does not exist.

I think the above instructions are excellent and I often send this blog post to my clients.